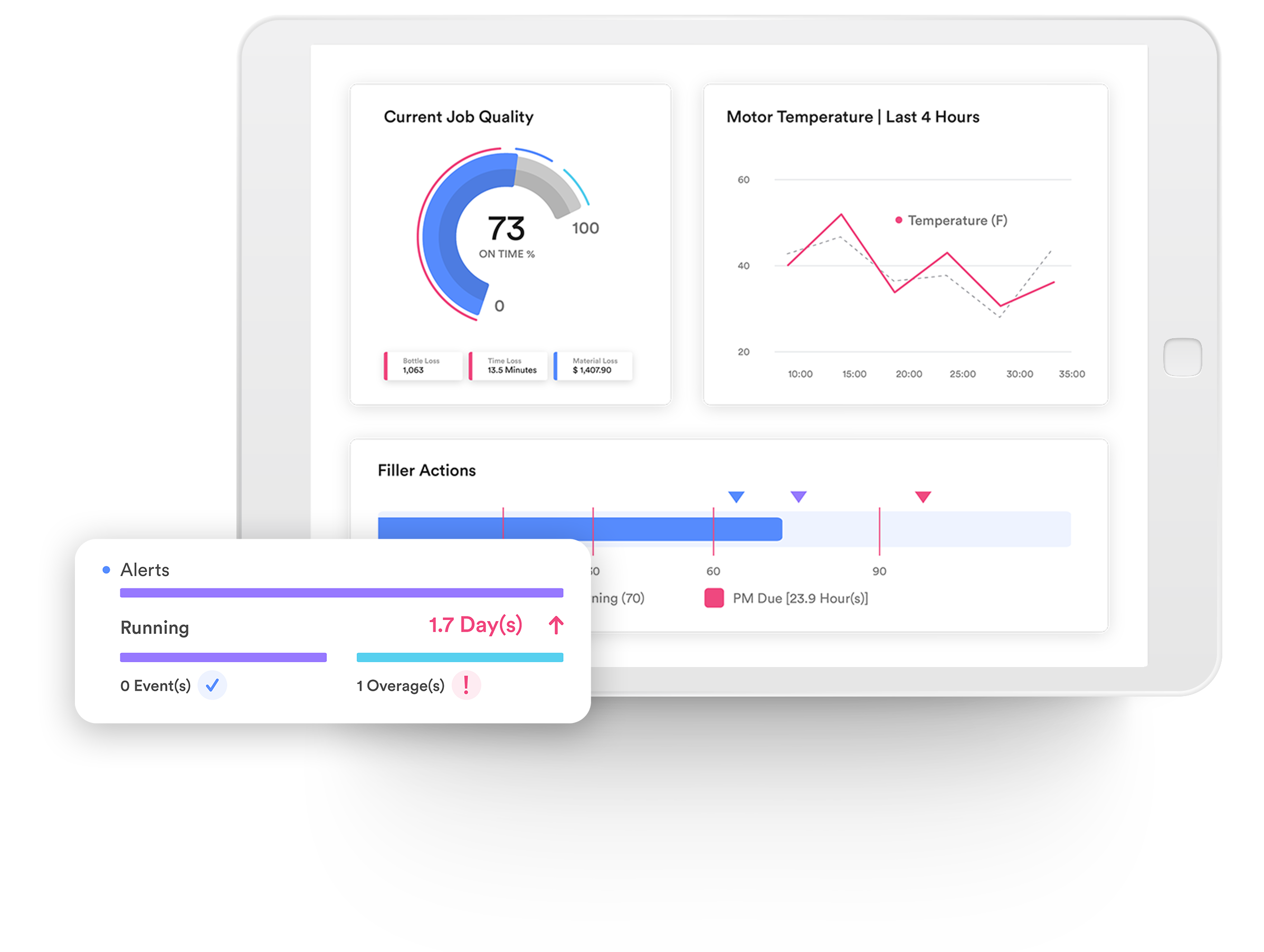

One Platform, Many Solutions

From production scheduling and inventory management to quality control, maintenance, and beyond, TrakSYS provides you with the MES solutions and tools you need to run your operations as efficiently, effectively, and profitably as possible.

Take Control of Your Factory

TrakSYS has been designed to work the way you work: fast, flexible, and focused on solving specific business challenges. And we’ve created a set of pre-configured manufacturing execution system (MES) solutions that correspond with the challenges faced by our customers most frequently, such as OEE, E-Records, SPC, and more. So what do you want to do with TrakSYS? Start with one of our pre-configured MES solutions, or create your own using the platform’s powerful built-in configuration tools.

Traceability

Protect consumers, your brand, and your bottom line with enterprise-wide traceability.

What are You Working on Right Now?

Performance? Quality? E-Records? Tell us what you’re working on.

Chances are, we can help.